How to Automate Your Cannabis Harvest Without Damaging Your Flower

There's a way to automate your processes and maximize your results without removing any of the precious components of the delicate cannabis flower. Created with GreenBroz.

It’s 2020, and automation is already a standard operating procedure in most large-scale industries with consumer packaged goods. It’s only natural that the cannabis industry, one of the fastest-growing industries on the planet, would start to catch up with the rest of the commercial enterprise.

However, cannabis isn’t the same as dried beans or canned tuna. It is quite literally a delicate flower, and much of the equipment and machinery used to automate other agricultural industries is too rough with the exquisite buds that growers have painstakingly mothered for a season.

Photo courtesy of GreenBroz.

There’s so much hard work that goes into a grow op, it makes sense that some cultivators are trepidatious about letting machinery handle their flower. Trichomes can be easily knocked off, and terpenes can be damaged in storage. However, the cost of hiring labor to trim and sort those buds by hand can be enormous—not to mention time-consuming. But what if there was a way to automate while still protecting your product? That’s the question that GreenBroz has committed themselves to answering.

Save the Terps

Cannabis without terpenes is like a piece of fruit with no sweetness. Terpenes provide all the deliciously funky aromas and flavors we associate with herb. Some studies even suggest that terpenes help contribute to the medicinal effects of cannabis.

Next to the cannabinoids themselves, terpenes are the most important compound found in the plant. That’s why it’s crucial for growers to make sure those mouthwatering terps make it all the way from harvest to the grinder.

Photo courtesy of savetheterps.org

Once you cut down your cannabis, you’ve essentially killed the plant. Now the name of the game is preservation—maintaining those terpenes all the way through storage. In cannabis, terpenes are found in those sticky, crystalline trichomes that cover the buds and give it that glassy look. In order to keep them from deteriorating, proper humidity control is essential. By storing buds in an airtight container with the addition of a saturated salt solution or moisture packet, terpene evaporation can be effectively minimized.

Remember every second you spend sorting and trimming can expose the terpenes to suboptimal conditions. Minimizing the amount of time flower spends outside of a humidity controlled environment is vital to terp preservation.

One organization, SaveTheTerps, has made it their mission to educate consumers and manufacturers alike about the importance of keeping terpenes intact. By partnering with other industry leaders like GreenBroz and Boveda, SaveTheTerps is changing cannabis one trichome at a time.

Model M Dry Trimmer

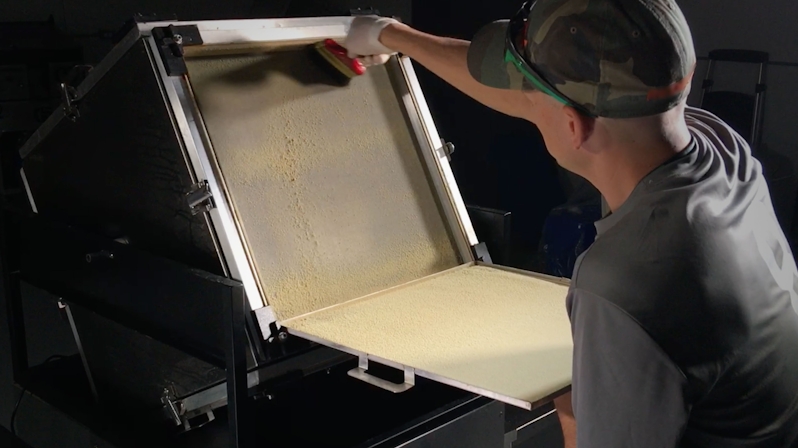

Photo courtesy of GreenBroz.

When dry trimming cannabis, the flower is hung to dry before it is trimmed. The extra leaves that would have been removed during a wet trim actually help to increase the humidity around the buds, and slow down the drying time. While dry trimming can eat up time and space, the decrease in drying time helps to prevent terpene loss.

It’s important to note that when dry trimming, the trichomes are drying as well. As those trichomes dry out, they become more brittle, and can break off if not carefully handled. Here’s where the new Model M Dry Trimmer from GreenBroz comes in.

Photo courtesy of GreenBroz.

The surgical steel trimmer blade on the Model M is designed to maintain purity throughout the entire trimming process. The patented design of the blade’s angle allows for a gentle rolling of product as opposed to the violent end-over-end machine style you see with other brands. This delicate trimming process helps to prevent trichrome breakage.

The Model M also allows the operator to keep their eyes on the flower during the trimming process, unlike other dry trimmers where your beautiful buds disappear into one end and (hopefully) come out the other. This allows cultivators to customize their trimming. With the Model M, you can have the best of both worlds: machine trim partly to cut down on labor costs, and finish with artisan hand trim.

Photo courtesy of GreenBroz.

Don’t let the Model M’s gentleness deceive you. Despite its soft touch the Model M is modestly estimated to be capable of manicuring twelve+ pounds an hour!

Precision Sorter

Photo courtesy of GreenBroz.

Sorting your cannabis flower into similar size batches before dropping them in the trimmer can go a long way to getting a more uniform trim. After the trimming process is complete, another sorting is required so you can package based on bud size, and separate your shake and smalls for pre-rolls and extraction. Those little buds are perfect for the PurePressure Long Peaks Resin Press.

Whether you’re pre-sorting buds to optimize trimming, or post-sorting for ideal packaging, every second spent handling your flower outside of a humidity controlled environment can contribute to terpene degradation, which is why it is so important to sort as quickly as possible. The GreenBroz Precision Sorter is capable of sorting flower at the obscenely fast rate of 1.5 pounds a minute.

Like all GreenBroz equipment, the Precision Sorter is designed to carefully cradle cannabis, and take care of those precious trichomes. Unlike other sorting equipment that utilizes vibrations to move product around, the GreenBroz Precision Sorter uses a gentle conveyor belt system that encourages terpene retention.

Alchemist 420 Trichome Extractor

Photo courtesy of GreenBroz.

Now you’ve trimmed, sorted, and packaged your bud, but there’s still some delicious terpenes we don’t want to forget about—the trim!

The Alchemist 420 Trichome Extractor is a dry-sift, solvent-free extractor that pairs perfectly with the Model M Trimmer. All of the trim that is taken off by the Model M is collected by the trimmer without the use of any hoses or vacuums in order to maintain maximum trichome retention. That excess trim can be taken and dropped directly into the Alchemist 420 Trichome Extractor and transformed into kief.

Photo courtesy of GreenBroz.

The Alchemist 420 can be used by itself, or with the addition of pulverized dry ice. It comes equipped with 180 Micron Screens that are designed to provide both the highest yield, and highest quality product possible.

Automate your Harvest

By automating your harvest, you can cut labor costs, and pass those savings on to your grateful customers. Without the burden of tedious trimming duties, your employees can be freed up to focus on cultivating the best possible product. Just make sure you invest in industry-born technology that’s designed to #savetheterps!

Herb Recommended Products:

READ MORE